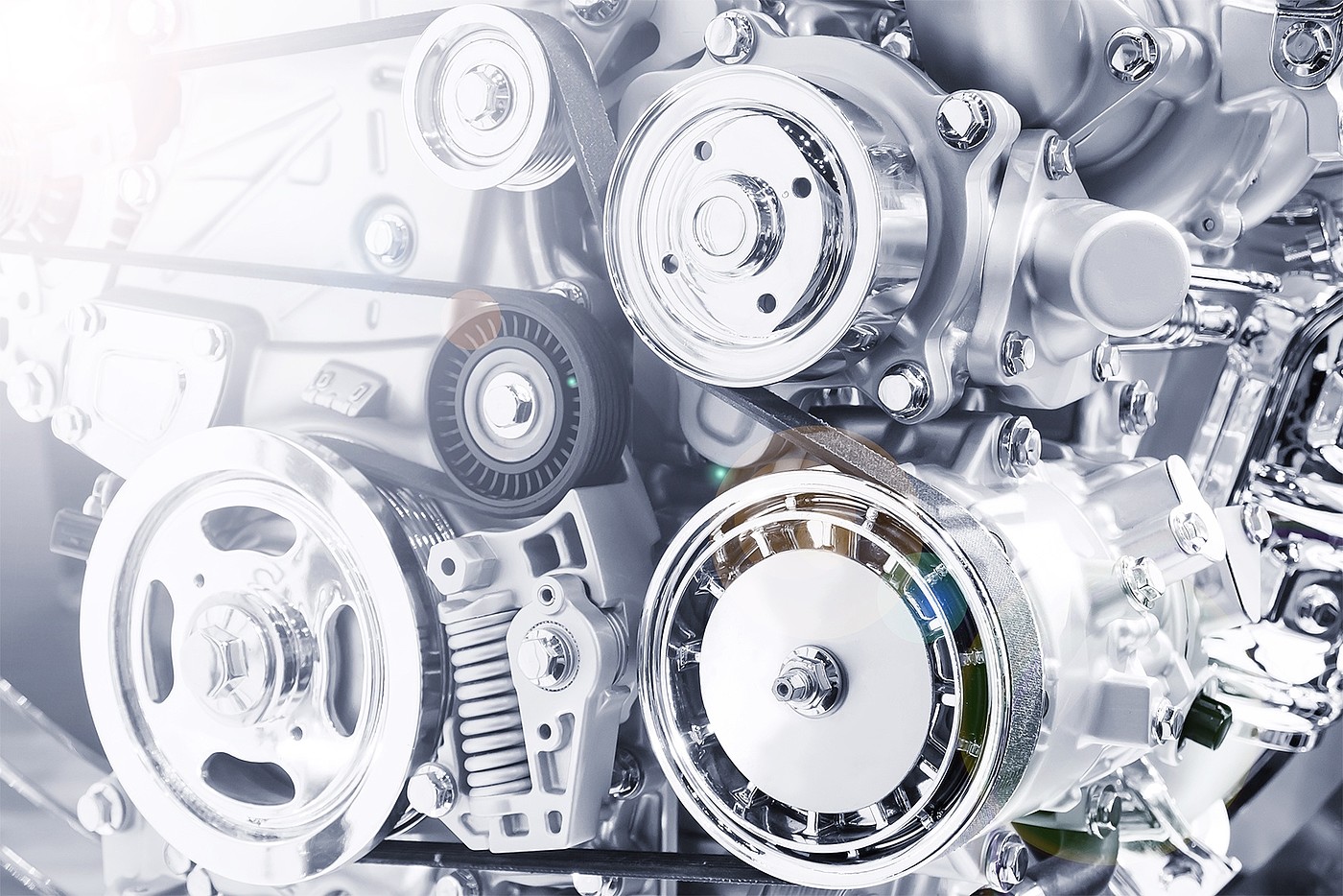

Process and product data management in automobile development shapes, controls, monitors and improves developmental processes with the objective of achieving process orientation throughout. After all, this is something that becomes apparent in product quality. Furthermore, reaching ambitious milestones does not have to be accidental. Instead, it can be guaranteed with uncompromising process orientation. Not just once, but always.

We are responsible for all of the processes in the development or start-up phase that are needed for achieving project milestones. We always have one target: guaranteeing component part and vehicle release corresponding to the status both in day-to-day business and in overall development projects. Your process of product evolution provides the foundation for your actions.

Our expertise is geared to the our customers' fields of technical development : electrical/electronic engineering, body and equipment, overall vehicle, chassis and drive.

We offer the following solutions and services to meet your needs:

Process management

- Selection of suppliers, requesting quotations and assessing these with regard to cost, quality and target dates

- Definition of manufacturing processes in line with individual component requirements

- Coordination of project deadlines and guaranteeing component availability

- Process analysis and system-based documentation

Competence centre change management

- Qualified component change handling

- Monitoring of technology, schedule, costs

- Controlling changes

- Documenting changes

- Presentation of proposed amendments in decision-making committees

Vehicle management

- Test vehicle planning in accordance with project assumptions

- Experimental vehicle planning

- Vehicle ordering and vehicle handling

- Planning factory orders

- Coordination of endurance tests and approval drives

- Guaranteeing availability of components

BOM & approval management

- Approval process

- Standardized documentation of the design revision levels

- Evaluating special actions specific to the project

- Weight tracking/ axle load calculation

- Checking the data structure

Lokalization management

- Coordination and advancement of localization process worldwide

- Coordination assistance with joint ventures

- Putting on workshops on localization at foreign production sites

- Support for vehicle projects and supplier sourcing for new markets

Certification management

- Supporting component part development in conformity with the laws

- Drawing up and controlling approval-relevant documents all around the world

- Worldwide coordination of component certificates

Homologation

- Research of all laws necessary for certification in the sales markets

- Co-ordination with the technical and homologation departments

- Inclusion of criteria that are not yet available in status E

- Filling in local approval documents of various states

- Generation of approval reports on component volumes

- Determination of requirements, configuration and ordering of homologation vehicles

- Checking component product specifications with a view to legal conformity, consultation with author

- Worldwide shipment of components, bodies and vehicles, as well as withdrawal and scrapping

Version management

- Controlling and tracking stocks of hardware and software in prototype, pre-series and series vehicles

- Drawing up and complying with installation rules for control unit versions and the ODX baseline

Initial start-up/ software updates

- Flashing, encoding, configuring, customising and basic settings of control units

- Analysis for troubleshooting hardware and software

- Support and coordination of the entire approval process

- Analysis of data streams in vehicle bus systems

Digital Mock Up

- Checking constructed space

- Installation and dismantling tests

- Proximity checks

- Construction feasibility tests

- Collision testing

Data management

- Data transfer

- Data preparation

- Advisory service to engineering/ design in all procedural issues concerning Workflow Management

- Data archiving and vehicle structure maintenance (Team Center)

Drawing checks

- Drawing checks in accordance with standards and directives

- Correction of drawings

Project back office

- Combination of contents

- Multi-location handling is possible

- Handling of small, medium and large order volumes

- Archiving design and development data

- Filling customers' systems

- Producing data consistency, Data conversion

Technical team management/ office

- Target-oriented monitoring of project milestones in technical teams

- Controlling specific project work

- Monitoring the current stage of development in the project

- Safe handling of customers' project-relevant systems and processes

Project coordination

- Systematic approval reporting

- Standardised visualisation

- Obtaining and processing information

- Data evaluation

- Action tracking

- Data plausibility checks