VEHICLE FUNCTIONS

Functionality is one of the strongest arguments for buying a car. Where comfort and safety functions are concerned, vehicle manufacturers have to not just constantly improve a vehicle's functions for their discerning customers, but also ensure that they can be directly experienced. No easy task, when we consider the increasing complexity and high degree of variance expected today. Nevertheless, this is a familiar task for us. In the development of vehicle functions, the all-round testing of the attributes of the complete vehicle is our responsibility. These include active and passive safety, longitudinal and lateral dynamics, operational stability, NVH, aerodynamics and aeroacoustics, as well as thermal management, HVAC and cooling. All with one aim: to improve vehicle functions for you and your customers.

Another element of our part in the function development process is guaranteeing the integration of the restraint system and heating and air conditioning components: from geometrical integration, to system supplier management, and finally to approval recommendation.

Vehicle safety

"Integral safety" is the coordinated interaction of active and passive safety requirements, and therefore compliance with the relevant safety requirements, including certification. For us, it means even more: our vehicle safety experts are already involved during the concept phase. A great advantage, as most of the modifications made to the vehicle's structure and interior components at this stage influence the deformation characteristics of the car in the event of a crash.

In turn, the front end package and design of its body in white and exterior parts influence the achievement of objectives in pedestrian protection and, to some extent, in passenger safety, too.

It is also, for instance, possible to use sensor data from active safety systems such as distance control or braking assistants etc. to pre-condition systems for passive safety or to activate them earlier.

The added value to you: greater safety for your customers and smooth, uncomplicated approval and homologation procedures.

Component development and integration

From the concept phase through to start of production, we optimise the function, cost and deadlines of the component families, seat belts, airbags, steering wheel and rollover protection system at module level. And, of course, integrate them in the complete vehicle. For seat belt anchorage, relay mechanism or windowbags: we are your experts for the integration of complex components.

Pedestrian Protection

When it comes to vehicle safety, it is no longer enough to concentrate on the passengers alone. In order to guarantee the safety of both the driver and other road users, it is necessary to keep an eye on everything that is going on around the vehicle. This means that, for us, pedestrian protection is a key element of vehicle development.

Our expert knowledge, which begins with project management and simulation, covers all areas through to testing on our fully equipped test stands. At many sites, and also close to you.

We offer the following solutions and services to meet your needs:

TESTING / CAE

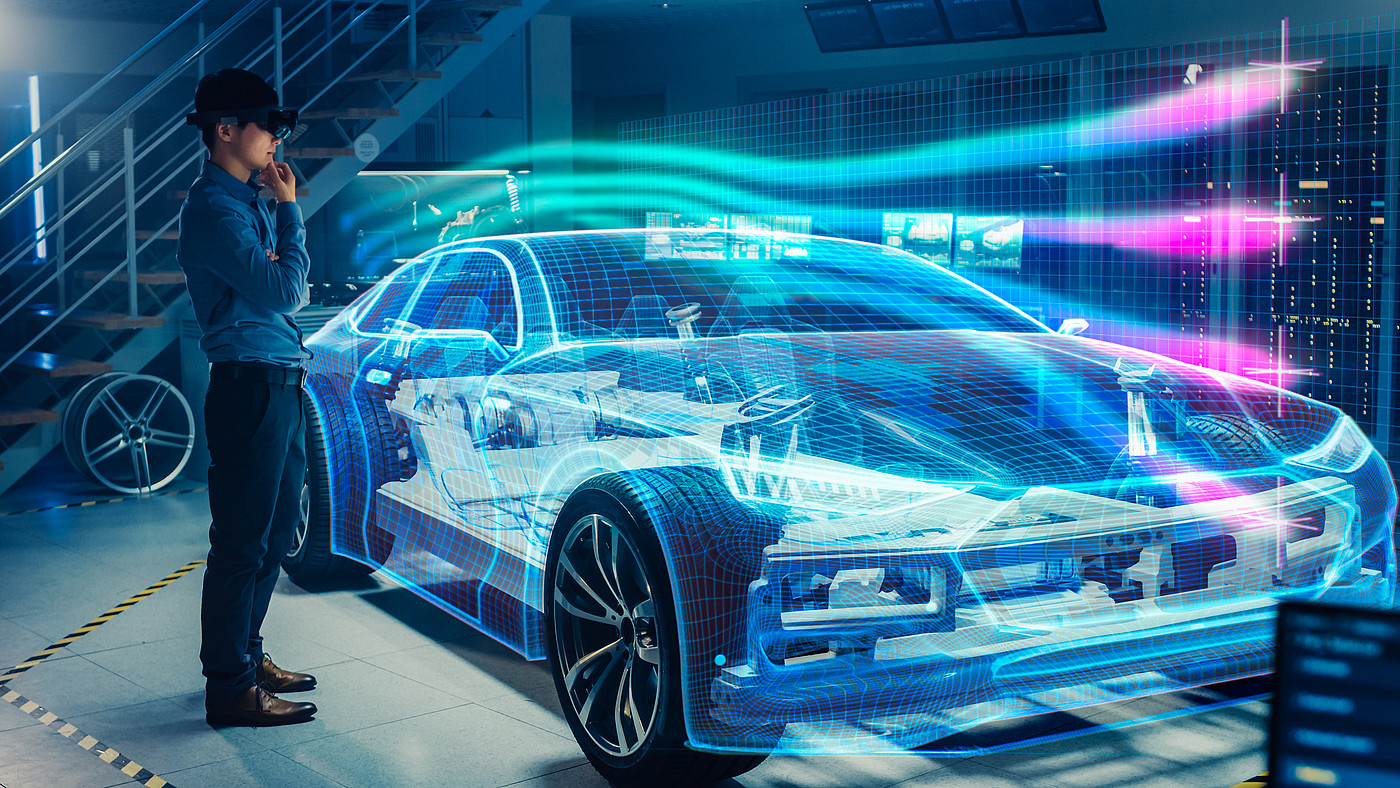

A solution is only as good as the results it provides when put into practice. If you are involved in developing new, ground-breaking product concepts today, then you need to be sure that your solutions will do exactly what they are meant to when you come to apply them. With our all-round spectrum of testing services and in-depth knowledge, we know what really counts. Using virtual or real-life methods, components or complete vehicles, test systems or material testing in our own accredited test laboratory - we can come up with the right solution, and give you early, conclusive and validated feedback from real-life scenarios.

By validating products and product properties at an early stage, development periods are shortened, development costs reduced, and last but not least products improved. The key factors here are virtual simulation and testing within the framework of computer-aided engineering (CAE), because whatever can be simulated while the concept is still in its initial stages will not need to be constructed at a later date - a process which is both complex and expensive.

Our CAE experts support production development with the functional design of components, systems and complete vehicles. By applying virtual simulation and calculation, we are able to optimise the stresses of components, in this way reducing weight, to test various material concepts (e.g. steel, plastic, aluminium, GRP, CFRP) in intelligent networks with our test laboratories, and to carry out different load situations, including vehicle crashes. And if the existing software tools are unable to cover the desired application, we have a solution for that, too – our software team programmes tools for customers' specific applications, to optimise in-house process times and generate new solutions.

We offer the following solutions and services to meet your needs: